General and Heavy Engineering.

Welcome to 3D-LABS – Your Trusted Partner for General and Heavy Engineering Solutions

At 3D-LABS, we take immense pride in offering top-notch General and Heavy Engineering services that cater to a wide range of industries and projects. With years of experience and a team of skilled professionals, we are committed to delivering cutting-edge engineering solutions that exceed our clients’ expectations. Whether you’re looking for expert design, analysis, fabrication, or consultation services, 3D-LABS has you covered.

Our Comprehensive General and Heavy Engineering Services:

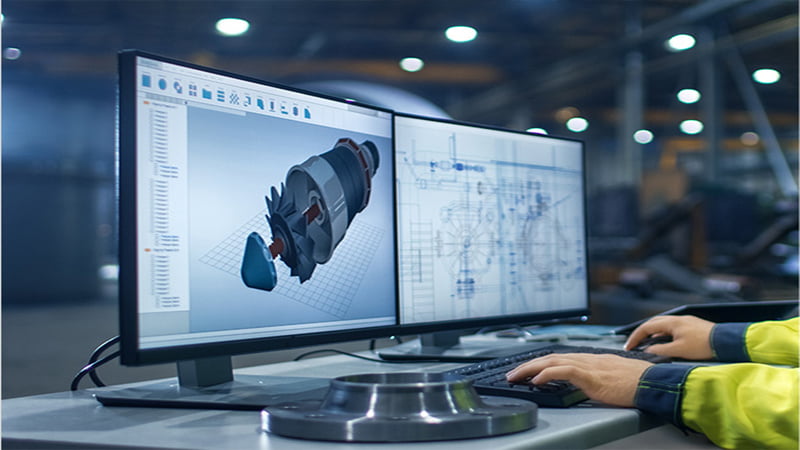

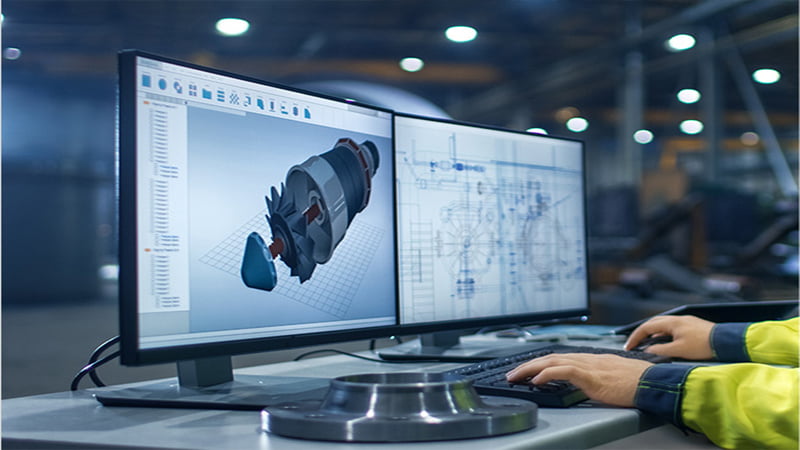

Engineering Design and Analysis:

Our team of experienced engineers excels in creating detailed engineering designs for a variety of projects. We utilize the latest software and technologies to provide accurate 3D modeling and simulations. Whether it’s a complex structure or a simple component, we ensure every detail is meticulously crafted to meet your project requirements.

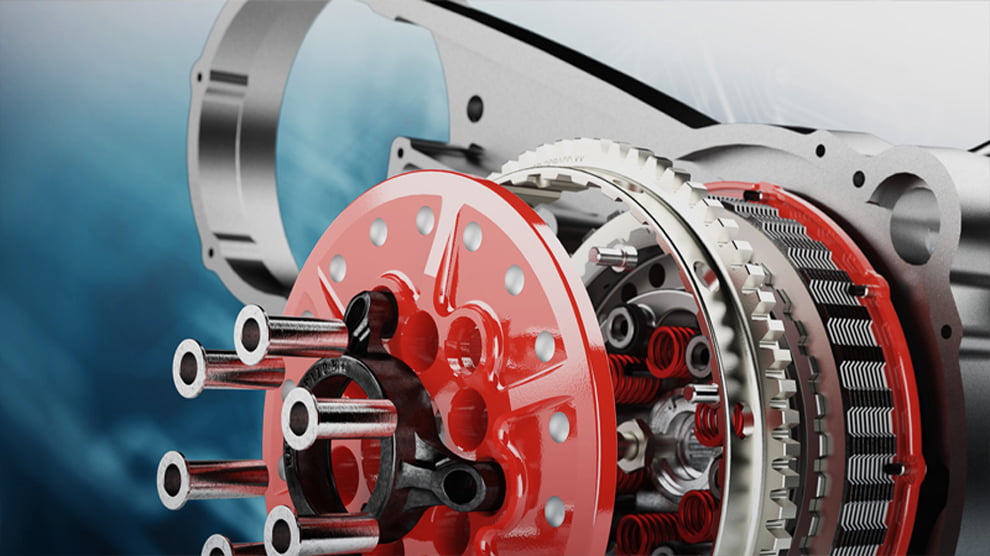

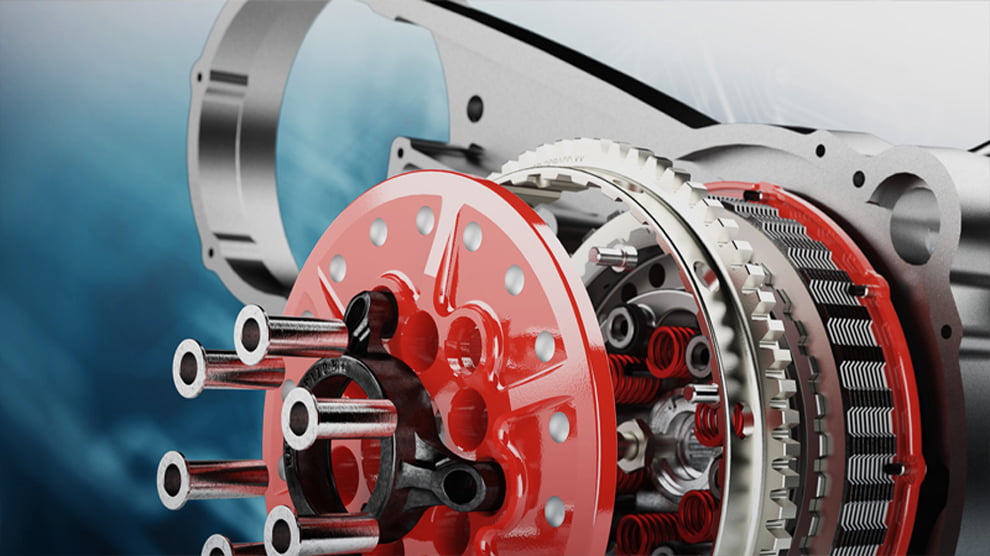

Fabrication and Manufacturing:

At 3D-LABS, we have a state-of-the-art fabrication facility equipped to handle heavy engineering projects. Our skilled technicians and advanced machinery enable us to produce high-quality components and equipment. From small-scale prototypes to large industrial machinery, we deliver reliable and robust solutions.

Structural Integrity and Safety Assessments:

Safety is our top priority. Our team conducts thorough structural integrity assessments to ensure that all engineering designs and fabricated components meet safety standards. We also offer risk analysis and provide recommendations to enhance safety measures.

Consultation and Project Management:

3D-LABS offers comprehensive consultation services to guide you through every stage of your engineering project. Our expert consultants can provide valuable insights, cost-effective solutions, and strategic planning to optimize your project’s success. Additionally, we can take charge of project management, ensuring that everything runs smoothly from start to finish.

Equipment Upgrades and Retrofits:

As technology evolves, so should your equipment. Our engineering team specializes in upgrading and retrofitting existing machinery and systems to enhance their performance, efficiency, and lifespan. Upgrading your equipment can save costs and improve productivity, and we are here to help you achieve that.

Industries We Serve:

Our General and Heavy Engineering services cater to a wide range of industries, including but not limited to:

Oil and Gas

Power Generation

Mining and Minerals

Manufacturing

Construction

Aerospace

Transportation

Why Choose 3D-LABS?

Expertise and Experience:

With years of experience in the engineering industry, our team has successfully completed numerous projects, gaining invaluable expertise along the way.

Cutting-Edge Technology:

We leverage the latest software and technologies to ensure precise engineering designs, efficient analysis, and high-quality fabrication.

Customized Solutions:

No project is the same, and we understand the uniqueness of each client’s requirements. Our solutions are tailor-made to suit your specific needs.

Timely Delivery:

We adhere to strict timelines and schedules, ensuring that your project is completed on time, every time.

Commitment to Quality:

Quality is at the core of everything we do. We maintain rigorous quality control measures to deliver flawless engineering solutions.

Contact us today to discuss your General and Heavy Engineering needs and discover how 3D-LABS can contribute to the success of your project. Our team is eager to collaborate with you and transform your ideas into reality.

Chemicals and Oil & Gas Engineering

Welcome to 3D-LABS – Your Trusted Partner for Chemicals and Oil & Gas Engineering Excellence

At 3D-LABS, we take immense pride in being a leading provider of advanced Chemicals and Oil & Gas Engineering services. With a profound understanding of the complexities of these industries, we offer innovative solutions that drive efficiency, safety, and sustainability. Our team of experienced engineers and experts is dedicated to delivering top-notch engineering services to help you achieve your project goals seamlessly.

Our Comprehensive Chemicals and Oil & Gas Engineering Services:

Process Engineering and Optimization:

Our Chemicals and Oil & Gas process engineering services focus on designing, optimizing, and improving production processes. We employ advanced simulation tools and analysis to identify bottlenecks, enhance productivity, and minimize operational costs. From conceptualization to commissioning, we support you throughout the project lifecycle.

Equipment Design and Fabrication:

In the Chemicals and Oil & Gas industries, precision-engineered equipment is crucial for safe and efficient operations. Our team excels in designing and fabricating equipment that complies with industry standards and regulations. We consider factors such as material compatibility, corrosion resistance, and operational requirements to deliver reliable and high-performance equipment.

Safety and Environmental Compliance:

Safety and environmental consciousness are integral to Chemicals and Oil & Gas engineering. At 3D-LABS, we conduct comprehensive safety assessments, risk analysis, and compliance evaluations to ensure your projects meet the highest safety standards and minimize environmental impact.

Piping and Instrumentation Diagram (P&ID) Development:

Accurate P&IDs are essential for understanding and managing complex processes in the Chemicals and Oil & Gas industries. Our engineering team excels in creating detailed P&IDs, aiding seamless communication, and facilitating efficient operations and maintenance.

Turnkey Project Solutions:

From concept to completion, we offer turnkey solutions for Chemicals and Oil & Gas projects. Our expertise in project management, engineering design, procurement, and construction ensures a streamlined and successful project execution.

Industries We Serve:

Our Chemicals and Oil & Gas Engineering services cater to a diverse range of industries, including but not limited to:

Petrochemicals

Refining

Specialty Chemicals

Natural Gas Processing

LNG (Liquefied Natural Gas)

Chemical Transportation and Storage

Why Choose 3D-LABS?

Industry Experience:

With years of experience serving the Chemicals and Oil & Gas sectors, we understand the unique challenges and requirements of these industries.

Skilled Engineering Team:

Our team of engineers and experts possesses in-depth knowledge and expertise, ensuring the highest level of technical competence in every project.

Innovative Solutions:

We leverage the latest technologies and industry best practices to deliver cutting-edge solutions that optimize your processes and drive business growth.

Focus on Safety and Sustainability:

Safety is at the forefront of everything we do. We strive to create engineering solutions that prioritize safety, while also promoting sustainability and environmental responsibility.

Client-Centric Approach:

At 3D-LABS, our clients’ success is our primary goal. We work closely with our clients, understanding their unique needs, and tailoring our services to deliver exceptional results.

Contact us today to explore how 3D-LABS can partner with your organization to provide unparalleled Chemicals and Oil & Gas Engineering solutions. Our team is ready to collaborate with you and bring your projects to fruition efficiently and effectively.

Aerospace & Defence

Welcome to 3D-LABS – Your Trusted Partner for Aerospace & Defence Engineering Excellence

At 3D-LABS, we are committed to delivering innovative Aerospace & Defence Engineering solutions that push the boundaries of technological advancements. With a profound passion for aviation, space, and defence industries, our team of skilled engineers and experts takes pride in providing cutting-edge solutions to meet the unique challenges faced in these sectors. Whether it’s aerospace design, defense systems, or advanced simulations, 3D-LABS is your go-to partner for superior engineering services.

Our Comprehensive Aerospace & Defence Engineering Services:

Aerospace Design and Analysis:

From conceptualizing new aircraft and UAVs to redesigning existing aerospace components, our aerospace engineering team excels in creating precise 3D models and simulations. We utilize state-of-the-art software and simulation tools to ensure aerodynamic efficiency, structural integrity, and optimal performance.

Defence Systems and Technology:

Our expertise in Defence Engineering extends to the development and enhancement of sophisticated defence systems and technologies. We focus on designing reliable and resilient defence solutions, encompassing land, air, and sea domains.

Aircraft Interiors and Cabin Design:

The comfort and safety of aircraft passengers are crucial aspects of the aerospace industry. Our engineering team specializes in creating ergonomic and aesthetically pleasing aircraft interiors while adhering to rigorous safety standards.

Simulation and Testing:

At 3D-LABS, we employ advanced simulations and testing methodologies to verify and validate aerospace and defence designs. Our simulations include stress analysis, thermal analysis, and fluid dynamics to ensure optimal performance and reliability.

Compliance and Certification Support:

Navigating the complex regulatory landscape of the aerospace and defence industries can be challenging. We offer compliance and certification support to ensure that your products and systems meet all necessary standards and approvals.

Industries We Serve:

Our Aerospace & Defence Engineering services cater to a diverse range of industries, including but not limited to:

Commercial Aviation

Military and Defence

Space Exploration

Unmanned Aerial Vehicles (UAVs)

Aerospace Manufacturing

Satellite Technology

Why Choose 3D-LABS?

Aerospace and Defence Expertise:

Our team comprises seasoned aerospace and defence engineers with a profound understanding of the industry’s intricacies.

Innovation and Technology:

We stay at the forefront of technology, leveraging the latest tools and methodologies to provide state-of-the-art engineering solutions.

Precision Engineering:

Our attention to detail and commitment to precision engineering ensure that every project is executed with utmost accuracy and efficiency.

Confidentiality and Security:

We prioritize the confidentiality and security of our clients’ projects, ensuring that sensitive information remains protected at all times.

Timely Delivery:

We understand the importance of meeting project deadlines, and our agile project management approach ensures timely delivery without compromising quality.

Contact us today to discuss your Aerospace & Defence Engineering requirements and explore how 3D-LABS can contribute to the success of your next aviation, space, or defence project. Our dedicated team is eager to collaborate with you and turn your visionary ideas into reality.

Food and Water Storage Systems

Welcome to 3D-LABS – Your Reliable Partner for Cutting-Edge Food and Water Storage Solutions

At 3D-LABS, we understand the critical importance of efficient and safe Food and Water Storage Systems. With a focus on sustainability and technological advancements, we offer innovative engineering solutions to address the storage needs of the food and water industries. Our team of experienced engineers and experts is dedicated to delivering high-quality, customized storage systems that ensure the preservation and availability of essential resources.

Our Comprehensive Food and Water Storage Systems:

Food Storage Solutions:

We specialize in designing and fabricating food storage systems that cater to various industries, including agriculture, food processing, and distribution. Our expertise includes bulk storage silos, climate-controlled storage facilities, and innovative packaging solutions to preserve the quality and freshness of perishable goods.

Water Storage and Treatment:

Water is a precious resource, and our engineering team is committed to providing sustainable water storage and treatment solutions. We offer water storage tanks, reservoirs, and rainwater harvesting systems that support efficient water management and conservation.

Customized Storage Design:

At 3D-LABS, we understand that each client’s storage requirements are unique. Our team works closely with you to understand your specific needs and tailors the design and engineering of storage systems accordingly.

Safety and Compliance:

Food and water storage systems must adhere to stringent safety and regulatory standards. We ensure that all our solutions meet the necessary industry compliance and safety requirements.

Maintenance and Optimization:

Our services extend beyond initial design and installation. We offer maintenance support and optimization services to ensure that your food and water storage systems continue to perform optimally over time.

Industries We Serve:

Our Food and Water Storage Systems cater to a diverse range of industries, including but not limited to:

Agriculture and Farming

Food Processing and Distribution

Beverage Industry

Hospitality and Restaurants

Municipal Water Management

Environmental Conservation

Why Choose 3D-LABS?

Extensive Industry Experience:

With years of experience in engineering and design, our team possesses in-depth knowledge of the food and water storage industries.

Technological Expertise:

We leverage the latest technologies, including 3D modeling and simulation, to deliver state-of-the-art storage solutions that optimize space and efficiency.

Sustainable Solutions:

At 3D-LABS, we are committed to sustainability. Our solutions aim to reduce waste, conserve resources, and minimize environmental impact.

Collaborative Approach:

We believe in open communication and collaboration with our clients throughout the project journey, ensuring that their vision and requirements are met.

Timely Project Delivery:

We understand the importance of timely project completion. Our streamlined project management process ensures that deadlines are met without compromising on quality.

Contact us today to discuss your Food and Water Storage System needs and explore how 3D-LABS can contribute to the success of your storage projects. Our dedicated team is ready to collaborate with you and provide top-of-the-line solutions that meet your unique storage challenges.

Design Consultancy

Welcome to 3D-LABS – Your Trusted Partner for Design Consultancy Services

At 3D-LABS, we are passionate about empowering innovation and turning ideas into reality. As a leading design consultancy firm, we offer a comprehensive range of expert services to help businesses and organizations achieve their design goals efficiently and effectively. Our team of skilled designers, engineers, and creative thinkers collaborates with clients to provide tailored solutions that drive innovation, enhance productivity, and ensure a competitive edge.

Our Comprehensive Design Consultancy Services:

Conceptualization and Ideation:

At the heart of every successful design is a compelling concept. Our design consultancy team excels in brainstorming sessions and ideation workshops to explore creative ideas that align with your vision and objectives. From the seed of an idea to a well-defined concept, we help you lay a strong foundation for your project.

Product Design and Development:

Transforming ideas into tangible products requires a combination of creativity, technical expertise, and market insights. 3D-LABS’ design consultancy services cover the entire product design and development process – from initial sketches and 3D modeling to prototyping and manufacturing support.

Industrial Design and Aesthetics:

The aesthetics of a product play a crucial role in its success. Our industrial designers focus on creating visually appealing and user-centric designs that resonate with your target audience. We carefully consider form, function, and user experience to deliver designs that leave a lasting impression.

Mechanical and Engineering Design:

Our expertise extends beyond aesthetics. We provide robust mechanical and engineering design solutions that ensure the functionality, efficiency, and safety of your products. From intricate mechanisms to complex systems, we handle all aspects of engineering design with precision.

Design Validation and Simulation:

To minimize risks and optimize performance, our design consultancy team conducts thorough validation and simulation tests. We use advanced software and simulations to analyze structural integrity, stress, and fluid dynamics, ensuring that your designs meet industry standards and compliance.

Industries We Serve:

Our Design Consultancy services cater to a wide range of industries, including but not limited to:

Consumer Electronics

Automotive

Healthcare and Medical Devices

Home Appliances and Furniture

Industrial Equipment

Robotics and Automation

Why Choose 3D-LABS?

Multidisciplinary Team:

Our diverse team of designers, engineers, and experts brings a wealth of knowledge and experience to deliver holistic design solutions.

Client-Centric Approach:

We believe in active collaboration with our clients, understanding their unique challenges, and tailoring our services to meet their specific needs.

Innovation and Technology:

We stay ahead of the curve with the latest design tools and technologies, ensuring that our solutions are at the cutting edge of innovation.

Time-Efficient and Cost-Effective:

We understand the importance of timely project delivery and cost-efficiency. Our streamlined design processes save time and resources.

Confidentiality and Security:

We treat your intellectual property with the utmost confidentiality and employ stringent security measures to protect sensitive information.

Contact us today to discuss your design consultancy needs and explore how 3D-LABS can contribute to the success of your next design project. Our team is excited to collaborate with you and transform your ideas into exceptional designs that make a lasting impact.

Power and Energy Projects

Welcome to 3D-LABS – Your Trusted Partner for Cutting-Edge Power and Energy Projects

At 3D-LABS, we are committed to shaping a sustainable future through innovative Power and Energy Projects. As a leading engineering firm in the energy sector, we offer a comprehensive range of services to support the design, development, and implementation of power generation and energy infrastructure projects. Our team of experienced engineers and experts collaborates with clients to deliver high-impact solutions that drive efficiency, harness renewable resources, and meet the growing demands of the global energy landscape.

Our Comprehensive Power and Energy Projects Services:

Renewable Energy Solutions:

We believe in harnessing the power of renewable resources for a cleaner and greener tomorrow. Our expertise spans solar, wind, hydro, and biomass energy projects. From site assessment to engineering design and commissioning, we support every aspect of renewable energy infrastructure development.

Conventional Power Generation:

For conventional power projects, we provide comprehensive engineering solutions for thermal, gas, and combined-cycle power plants. Our team ensures optimal performance, efficiency, and compliance with industry regulations.

Electrical System Design and Integration:

A robust and reliable electrical system is vital for any power and energy project. Our engineering team excels in designing and integrating electrical systems that ensure seamless power distribution and control.

Energy Storage Solutions:

Energy storage plays a crucial role in the stability and reliability of power grids. We offer cutting-edge energy storage solutions, including battery storage and pumped hydro storage, to balance energy supply and demand effectively.

Grid Modernization and Smart Grid Solutions:

Our expertise extends to modernizing power grids and implementing smart grid technologies. We integrate advanced automation and monitoring systems to optimize energy distribution and improve grid resilience.

Industries We Serve:

Our Power and Energy Projects services cater to a diverse range of industries, including but not limited to:

Utilities and Power Companies

Renewable Energy Developers

Government and Public Sector

Industrial and Manufacturing

Commercial and Residential

Why Choose 3D-LABS?

Specialized Energy Engineering Team:

Our team of energy engineers possesses extensive knowledge and expertise in the power and energy sector, ensuring the success of your projects.

Emphasis on Sustainability:

We are dedicated to promoting sustainable energy solutions and reducing the carbon footprint of energy projects.

Advanced Technology and Simulation:

We leverage state-of-the-art software and simulation tools to optimize project design, reduce risks, and enhance performance.

Project Management Excellence:

Our streamlined project management approach ensures timely project delivery and effective communication at every stage.

Customer-Centric Solutions:

We prioritize our clients’ needs and goals, tailoring our services to meet their specific project requirements.

Contact us today to discuss your Power and Energy Projects and explore how 3D-LABS can be your trusted partner in creating a cleaner, more efficient energy future. Our team is eager to collaborate with you and contribute to the success of your next power and energy endeavor.

Research and Design and Training

Welcome to 3D-LABS – Your Gateway to Cutting-Edge Research, Design, and Training Solutions

At 3D-LABS, we are committed to fostering innovation and excellence through a comprehensive suite of services encompassing Research, Design, and Training. As a leading provider of engineering solutions, we offer a platform where groundbreaking ideas are nurtured, transformed into reality through expert design, and shared through professional training programs. Our team of skilled researchers, designers, and trainers collaborates with individuals and organizations to drive progress, enhance skillsets, and stay at the forefront of technological advancements.

Research Services:

Technology and Product Research:

Our research services lay the groundwork for innovative product development and technological advancements. Through in-depth market analysis and feasibility studies, we identify opportunities, assess risks, and guide clients in making informed decisions.

Prototyping and Proof of Concept:

We specialize in creating functional prototypes and proof-of-concept models to validate and refine ideas before full-scale production. Our prototyping expertise accelerates the development process and minimizes potential challenges.

Design Services:

Product Design and Development:

Transforming ideas into market-ready products requires creative vision and technical expertise. Our design team excels in creating aesthetically pleasing, ergonomic, and functional designs that resonate with end-users.

Industrial Design and Branding:

Our industrial designers focus on creating visually appealing designs that reinforce brand identity. We understand the power of aesthetics in connecting with consumers and work to make your products stand out in the market.

Training Programs:

Engineering and CAD Training:

We offer comprehensive training programs on engineering principles and Computer-Aided Design (CAD) software. Our expert trainers equip individuals and teams with the necessary skills to tackle complex engineering challenges.

Simulation and Analysis Training:

Unlock the potential of simulation tools with our specialized training programs. From Finite Element Analysis (FEA) to Computational Fluid Dynamics (CFD), we empower engineers to perform accurate simulations for robust product development.

Why Choose 3D-LABS?

Interdisciplinary Expertise:

Our team comprises experts from diverse fields, ensuring a holistic approach to research, design, and training solutions.

State-of-the-Art Facilities:

We boast cutting-edge technology and resources, enabling us to deliver superior results and training experiences.

Client-Centric Approach:

At 3D-LABS, our clients’ success is our priority. We actively engage with our clients to understand their goals and tailor our services accordingly.

Innovation-driven Culture:

We foster an environment of innovation and continuous learning, pushing the boundaries of what’s possible in research, design, and training.

Confidentiality and Security:

We treat all research and design projects with the utmost confidentiality and employ stringent security measures to safeguard client data.

Contact us today to embark on a journey of research, design, and training with 3D-LABS. Our dedicated team is ready to collaborate with you and provide transformative solutions that drive progress and elevate your capabilities in the ever-evolving technological landscape.

Civil & Infrastructure

Welcome to 3D-LABS – Your Trusted Partner for Innovative Civil & Infrastructure Engineering Solutions

At 3D-LABS, we take pride in our expertise in Civil & Infrastructure Engineering, where we strive to shape the world with sustainable, resilient, and efficient infrastructure solutions. With a focus on cutting-edge technology and industry best practices, our team of skilled civil engineers and experts is committed to delivering high-quality engineering services that address the evolving needs of urban development, transportation, and infrastructure projects.

Our Comprehensive Civil & Infrastructure Engineering Services:

Structural Engineering and Design:

Our civil engineering team specializes in designing robust and efficient structures that withstand various loads and environmental conditions. From bridges to buildings, we ensure structural integrity, safety, and compliance with relevant codes and standards.

Transportation and Traffic Engineering:

Efficient transportation systems are the backbone of thriving communities. We provide comprehensive transportation engineering services, including road design, traffic management, and public transit planning, to enhance mobility and reduce congestion.

Water Resource Management:

We contribute to sustainable water resource management through innovative solutions for stormwater management, drainage systems, flood control, and wastewater treatment. Our engineering solutions promote environmental conservation and water efficiency.

Urban Planning and Development:

We embrace smart urban planning principles to create vibrant, functional, and livable urban spaces. Our expertise includes master planning, land development, and urban renewal projects that cater to the needs of growing populations.

Geotechnical and Foundation Engineering:

A solid foundation is essential for every infrastructure project. Our geotechnical engineering services encompass soil analysis, slope stability assessments, and foundation design to ensure safe and reliable construction.

Industries We Serve:

Our Civil & Infrastructure Engineering services cater to a diverse range of industries, including but not limited to:

Government and Public Sector

Real Estate and Property Development

Transportation and Infrastructure Agencies

Industrial and Commercial Developers

Environmental Conservation Organizations

Why Choose 3D-LABS?

Civil Engineering Expertise:

Our team of civil engineers possesses in-depth knowledge and experience in designing and implementing a wide range of infrastructure projects.

Emphasis on Sustainability:

We integrate sustainability principles into our engineering solutions, striving to minimize environmental impact and promote eco-friendly practices.

Advanced Design and Simulation Tools:

We leverage state-of-the-art design software and simulations to optimize infrastructure design, minimize risks, and enhance performance.

Collaborative Approach:

We actively collaborate with our clients, understanding their unique requirements, and involving them throughout the project journey.

Timely and Cost-Effective Solutions:

We value timely project delivery and cost-efficiency, adhering to budgets and schedules without compromising on quality.

Contact us today to discuss your Civil & Infrastructure Engineering needs and explore how 3D-LABS can contribute to the success of your next infrastructure project. Our dedicated team is ready to collaborate with you and provide exceptional engineering solutions that shape the world for the better.

Real Estate

Welcome to 3D-LABS – Your Trusted Partner for Cutting-Edge Real Estate Solutions

At 3D-LABS, we understand the dynamic nature of the real estate industry and its constant demand for innovative solutions. As a leading provider of advanced real estate services, we offer a comprehensive range of solutions to enhance the design, development, and marketing of real estate projects. Our team of experienced professionals excels in delivering visually compelling, accurate, and immersive solutions that bring real estate visions to life.

Our Comprehensive Real Estate Services:

Architectural Visualization:

Immerse your clients in captivating virtual experiences with our state-of-the-art architectural visualization services. We create high-quality 3D renderings and walkthroughs that allow potential buyers to explore and envision the property’s design and layout.

Realistic 3D Modeling:

Our expert 3D modelers breathe life into real estate projects by creating realistic 3D models of buildings, interiors, and landscapes. These detailed models aid in design review, planning, and marketing efforts.

Virtual Reality (VR) Tours:

Set yourself apart from the competition by offering virtual reality tours of your real estate developments. With our VR solutions, clients can virtually step into properties and experience them as if they were physically present.

3D Floor Plans and Site Plans:

We provide accurate and visually appealing 3D floor plans and site plans that offer a comprehensive view of the property’s layout, dimensions, and features, helping clients make informed decisions.

Real Estate Marketing Collateral:

Our design team can assist with creating eye-catching brochures, marketing materials, and multimedia presentations that effectively showcase real estate projects and attract potential buyers.

Industries We Serve:

Our Real Estate services cater to a diverse range of industries, including but not limited to:

Residential Real Estate

Commercial Real Estate

Hospitality and Resorts

Retail and Shopping Centers

Real Estate Developers and Agents

Why Choose 3D-LABS?

Expertise in Real Estate Visualization:

Our team specializes in real estate visualization, possessing the skill and knowledge to deliver compelling and accurate representations of your projects.

Cutting-Edge Technology:

We leverage the latest tools and technologies to offer innovative solutions that set your real estate developments apart from the competition.

Customization and Personalization:

We understand that each real estate project is unique. Our services are tailored to meet your specific requirements and objectives.

Quick Turnaround:

We value your time and strive to deliver our services promptly, ensuring your marketing and sales efforts stay on track.

Client Satisfaction:

Our dedication to client satisfaction drives us to exceed expectations and provide exceptional customer service at every stage of the project.

Contact us today to discuss your Real Estate Visualization needs and explore how 3D-LABS can elevate your real estate projects to new heights. Our passionate team is ready to collaborate with you and bring your vision to life with captivating and immersive solutions.

Information Technology

Welcome to 3D-LABS – Your Trusted Partner for Innovative Information Technology Solutions

At 3D-LABS, we embrace the transformative power of Information Technology (IT) to elevate businesses and organizations to new heights. As a leading provider of advanced IT services, we offer a comprehensive range of solutions that streamline operations, enhance efficiency, and drive digital transformation. Our team of skilled IT professionals and experts is committed to delivering tailor-made solutions that align with your unique business goals and objectives.

Our Comprehensive Information Technology Services:

Custom Software Development:

We specialize in creating bespoke software solutions tailored to your specific needs. Whether you require a web application, mobile app, or enterprise software, our expert developers ensure high-performance and user-friendly experiences.

IT Infrastructure Services:

Our IT infrastructure services encompass design, implementation, and maintenance of robust and scalable IT systems. We optimize your infrastructure for maximum performance, security, and reliability.

Cloud Solutions and Migration:

Embrace the agility and scalability of cloud computing with our cloud solutions and migration services. We help you transition seamlessly to the cloud, ensuring data security and cost-efficiency.

Cybersecurity and Data Protection:

Protect your business from evolving cyber threats with our comprehensive cybersecurity solutions. We implement robust security measures and data protection protocols to safeguard your critical assets.

IT Consultancy and Support:

Our IT consultancy services provide strategic insights to optimize your IT ecosystem. Additionally, our dedicated support team ensures your IT infrastructure runs smoothly, minimizing downtime and disruptions.

Industries We Serve:

Our Information Technology services cater to a diverse range of industries, including but not limited to:

Banking and Finance

Healthcare and Medical

Education and E-Learning

Retail and E-Commerce

Manufacturing and Supply Chain

Government and Public Sector

Why Choose 3D-LABS?

Expert IT Professionals:

Our team comprises seasoned IT professionals with a wealth of experience in designing and implementing cutting-edge solutions.

Customization and Scalability:

We understand that one size does not fit all. Our solutions are customized to suit your specific needs and are designed to scale with your business.

Emphasis on Data Security:

Data security is a top priority. We implement robust measures to protect your sensitive information and ensure compliance with data regulations.

Timely Project Delivery:

We value your time and strive to deliver projects within agreed timelines, minimizing downtime and maximizing productivity.

Long-Term Partnership:

Our commitment to client satisfaction goes beyond project completion. We build lasting partnerships and provide ongoing support to meet evolving needs.

Contact us today to discuss your Information Technology requirements and explore how 3D-LABS can be your trusted partner in leveraging technology for business success. Our dedicated team is ready to collaborate with you and provide innovative IT solutions that empower your organization to thrive in the digital era.

Inventions

Welcome to 3D-LABS – Your Gateway to Groundbreaking Inventions

At 3D-LABS, we are passionate about turning visionary ideas into revolutionary inventions that shape the future. As a leading innovation hub, we offer a comprehensive suite of services to nurture, design, and bring inventions to life. Our team of creative thinkers, skilled engineers, and experts is committed to empowering innovators and inventors in their journey towards transformative breakthroughs.

Our Comprehensive Inventions Services:

Ideation and Conceptualization:

Every groundbreaking invention starts with a brilliant idea. Our team of innovation specialists conducts brainstorming sessions and ideation workshops to cultivate ideas into solid concepts.

Product Design and Engineering:

We excel in translating conceptual inventions into tangible products through expert product design and engineering services. From 3D modeling to prototyping, we ensure your inventions take shape with precision.

Intellectual Property Support:

Protecting your intellectual property is vital. We offer support in patent research, drafting, and filing, safeguarding your inventions from infringement and ensuring they remain solely yours.

Feasibility Studies and Market Analysis:

Understanding the market landscape and assessing the feasibility of your inventions are crucial steps. We conduct comprehensive market studies and feasibility analysis to guide you in making informed decisions.

Commercialization Assistance:

Monetizing your inventions requires a strategic approach. Our team provides commercialization assistance, helping you reach target markets and potential investors effectively.

Industries We Serve:

Our Inventions services cater to innovators and inventors across diverse industries, including but not limited to:

Technology and Electronics

Healthcare and Medical Devices

Consumer Goods and Appliances

Sustainable Energy and Environment

Transportation and Mobility

Why Choose 3D-LABS?

Innovation-Driven Culture:

As passionate innovators ourselves, we foster an environment that encourages creativity and fosters a culture of innovation.

Multidisciplinary Expertise:

Our diverse team of experts from various fields ensures a holistic approach to turning ideas into inventions.

Cutting-Edge Technology:

We leverage state-of-the-art technology, such as 3D printing and advanced simulations, to accelerate the invention development process.

Confidentiality and Integrity:

We prioritize the confidentiality and integrity of our clients’ inventions, implementing stringent security measures to protect their intellectual property.

Long-Term Partnership:

Our commitment to success extends beyond the completion of the invention process. We build lasting partnerships to support the growth and evolution of your inventions.

Contact us today to embark on a journey of innovation with 3D-LABS. Our dedicated team is eager to collaborate with you, turning your groundbreaking inventions into reality and propelling humanity into a brighter future.

Food and Health Care

Welcome to 3D-LABS – Your Trusted Partner for Pioneering Food and Healthcare Innovations

At 3D-LABS, we believe in the profound impact of revolutionary advancements in Food and Healthcare. As a leading provider of cutting-edge engineering and design solutions, we offer comprehensive services that contribute to healthier lives and improved well-being. Our team of experienced professionals is committed to collaborating with the Food and Healthcare industries to create innovative products, technologies, and solutions that elevate human health and nutrition.

Our Comprehensive Food and Healthcare Services:

Food Processing and Packaging Solutions:

In the ever-evolving food industry, we excel in designing advanced food processing and packaging solutions. From optimizing food production lines to creating sustainable packaging materials, we help deliver safe, nutritious, and appealing products to consumers.

Medical Devices and Equipment:

Our expertise extends to designing and developing state-of-the-art medical devices and equipment. We prioritize user-centric design and compliance with regulatory standards to ensure efficient and safe healthcare delivery.

Health Technology Solutions:

Embrace the power of technology in healthcare with our health technology solutions. From telemedicine platforms to digital health apps, we contribute to enhanced patient care, remote monitoring, and health data analytics.

Nutritional and Health Supplements:

We support the nutritional and health supplement industries with innovative product formulations and packaging designs. Our solutions aim to address specific health needs and promote overall well-being.

Regulatory Compliance and Certifications:

Navigating the complex regulatory landscape is crucial in the Food and Healthcare sectors. We provide guidance and support in meeting industry standards and obtaining necessary certifications.

Industries We Serve:

Our Food and Healthcare services cater to a diverse range of industries, including but not limited to:

Food Processing and Manufacturing

Nutraceuticals and Dietary Supplements

Pharmaceuticals and Biotechnology

Medical Device Manufacturers

Healthcare Providers and Facilities

Why Choose 3D-LABS?

Expertise in Food and Healthcare Engineering:

Our team possesses specialized knowledge and experience in designing solutions for the Food and Healthcare sectors.

Innovation and Technology:

We leverage the latest technologies, including 3D modeling and simulations, to drive innovation and efficiency in our solutions.

Safety and Compliance:

We prioritize safety, quality, and regulatory compliance in all our Food and Healthcare projects.

Collaborative Approach:

We work closely with our clients to understand their unique needs and challenges, fostering a collaborative partnership for success.

Customer-Centric Solutions:

Our client’s satisfaction is at the core of our services, and we are committed to delivering solutions that meet their specific requirements.

Contact us today to explore how 3D-LABS can contribute to the success of your Food and Healthcare projects. Our dedicated team is ready to collaborate with you in creating groundbreaking solutions that positively impact human health and well-being.